How to choose chipper blades?

2023-02-20

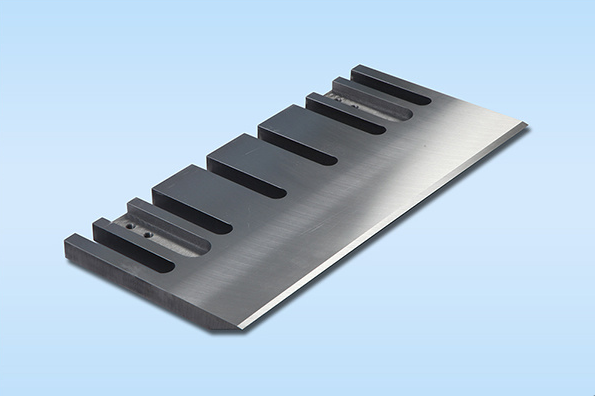

In wood chippers, the blades are the most easily damaged parts, and their lifespan is a major concern for users. Therefore, choosing a good set of blades for the chipper is crucial.

Generally, chipper blades are made of alloy steel, professionally heat-treated to achieve a hardness of HRC55-58°. This ensures a long-lasting sharp and wear-resistant cutting edge, guaranteeing high-quality wood chips and production efficiency.

The blade thickness can be controlled between 2~20mm. The sharp cutting edge results in excellent pulverization, with a smooth, mirror-like surface. The blades are wear-resistant, uniformly hard, produce clean cuts, offer good stability, and boast a continuous production time twice the industry average.

Increasing blade thickness and angle prevents blade deflection, effectively transferring cutting force. A variety of blade shapes are designed to meet different customer needs.

The chipper's alloy blades are durable, reliable, and advanced, extending service life. The unique pulverization system design significantly improves equipment lifespan. The pulverization chamber uses a multi-stage pulverization process and fine crushing principle, characterized by high impact force, high production efficiency, and strong fine crushing capabilities.

The sharpness of the chipper blades directly affects the quality of the chips. Flying knives can be single-edged or double-edged, while drum chipper bottom knives often use four-sided blades. Single-edged blades tend to create fragmented material; double-edged blades are suitable for hard and frozen materials. The grinding angle of the blade should be determined according to the material being cut. When cutting hard or frozen materials, the grinding angle should be larger, while a smaller angle is suitable for soft materials. This ensures good cutting quality and reduces energy consumption. To maintain blade sharpness, regular sharpening and replacement are necessary. Under normal circumstances, flying knives should be sharpened or replaced every 4-8 hours, and bottom knives every half-month.

Different types of wood have different toughness and varying ease of cutting, making blade selection crucial. Alloy steel blades are commonly used due to their high hardness, but prolonged cutting can cause damage and shorten their lifespan. Therefore, careful blade selection is necessary, prioritizing those with high-density heat treatment and long lifespans. This improves both the overall machine lifespan and operational efficiency.

Previous:

Next:

Related Information

2023-02-20

Contact Us

Email:

Phone:

Address:

No. 96, Tieshan East Road, Dalian Development Zone (next to Wolong Industrial Park, Dongjiagou)